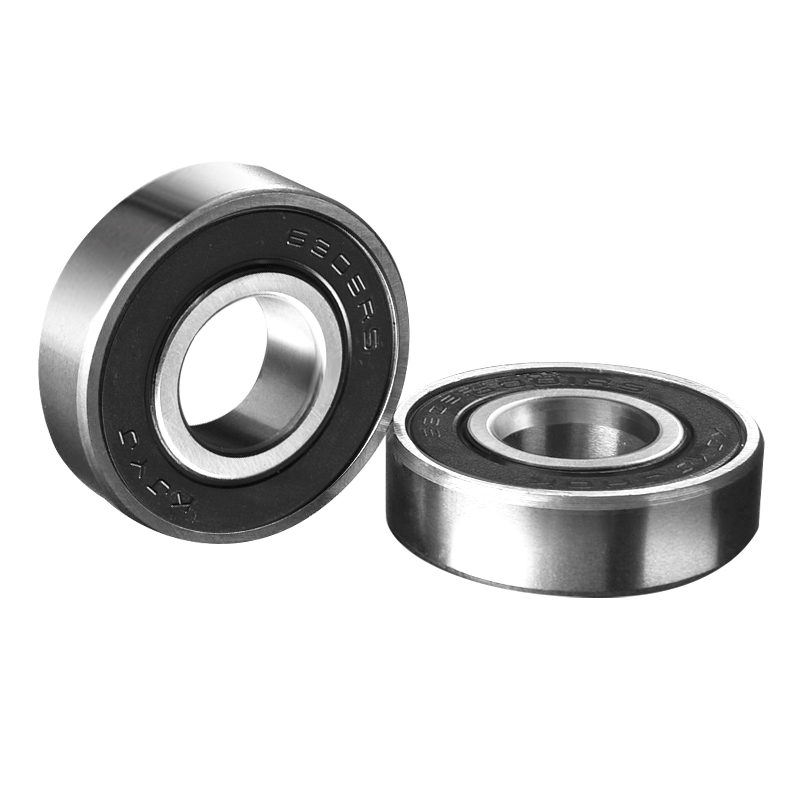

Yes, ball bearings can be used in scanners and play a critical role in many precision electronic devices, including scanners. Scanners need to achieve precise, smooth, and low-noise mechanical motion during operation, especially when the scanning head moves along the guide rail. Any small resistance, vibration, or deviation may affect the quality of the scanned image. Ball bearings are particularly suitable for use in equipment that requires high precision and smooth motion due to their characteristics of low friction, smooth operation, and precise positioning.

In scanners, ball bearings are commonly used to support the moving structure of scanning components, allowing them to move at high speed and smoothly on rails. Its function is to replace sliding friction with rolling friction, significantly reducing motion resistance, thereby improving mechanical response speed and scanning resolution. At the same time, due to the low starting torque and operating noise of ball bearings, it can ensure that the scanning head operates silently when moving, improving the user experience.

Ball bearings are compact in structure and suitable for equipment such as scanners that require high space utilization. High quality ball bearings also have strong wear resistance and good lifespan performance, which can maintain stable operation even in office equipment that is frequently used for a long time, reducing maintenance frequency and failure rate.

However, in order to meet the high requirements for cleanliness and accuracy of scanners, the ball bearings used are usually equipped with dust covers or sealing devices to prevent dust from entering and affecting their flexibility. At the same time, manufacturers will also make specialized optimizations in lubrication treatment and material selection, so that bearings can maintain lubrication without contaminating scanning parts or internal optical systems due to lubricant evaporation or leakage.

English

English 中文简体

中文简体

.png?imageView2/2/format/jp2)