Proper maintenance of motorcycle bearings is essential to ensure the smooth operation and long life of your motorcycle. Diligent bearing maintenance can reduce wear and damage, improve performance, and ultimately lower repair costs. Here are more detailed guidelines to help you effectively maintain motorcycle bearings:

Regular Lubrication:

Use the appropriate type of bearing grease recommended by the manufacturer.

Follow the manufacturer's specifications to ensure the correct amount of lubrication.

Refer to your motorcycle manual for the recommended lubrication frequency, as it may vary between different models.

Cleaning Bearings:

Motorcycle bearings are frequently exposed to dust, mud, and other contaminants.

Clean the bearings regularly using professional bearing cleaners and degreasers to remove old grease and impurities.

Ensure thorough drying after cleaning to prevent moisture from affecting the bearings.

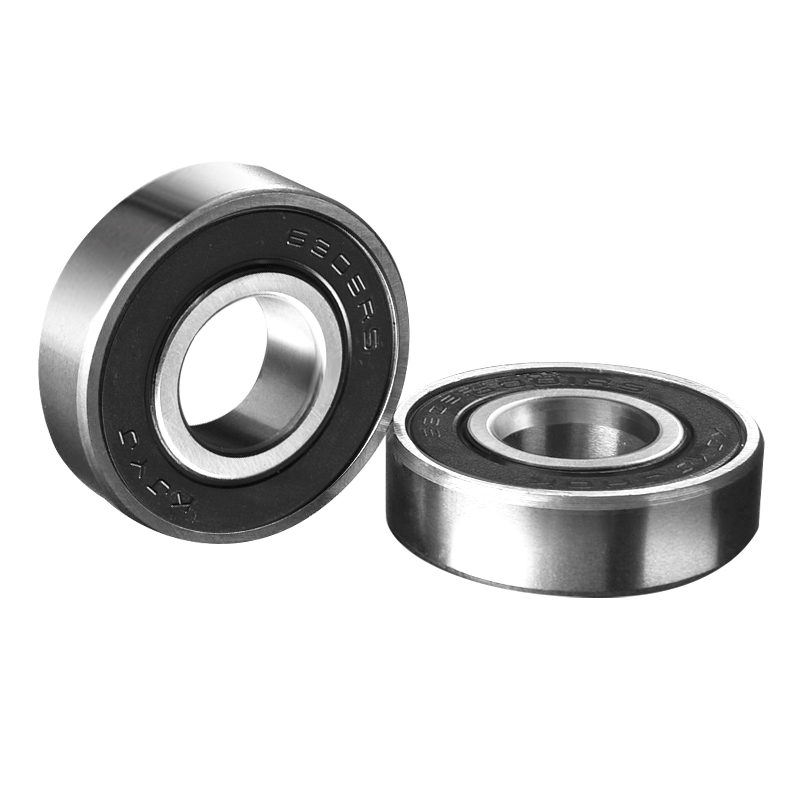

Inspect Seals:

Regularly check the seals around the bearings for signs of wear or damage.

Seals play a crucial role in protecting bearings from dust, moisture, and impurities.

Replace damaged seals promptly to prevent harmful substances from entering the bearing.

Prevent Overheating:

Avoid overheating of motorcycle bearings caused by extended high-speed riding, frequent hard braking, or overloading.

Practice cautious driving habits to prevent excessive loads and overheating.

Check Clearance and Preload:

Periodically inspect the clearance (looseness within the bearing) and preload (tightness between bearings).

If these parameters are not within normal range, make adjustments or replace the bearings as necessary.

Replace Worn Bearings:

If you notice your motorcycle vibrating, making creaking sounds, or feeling loose, inspect and replace worn bearings promptly.

Choose high-quality replacement bearings that meet the manufacturer's specifications for optimal reliability and performance.

Use Proper Tools:

When maintaining or replacing motorcycle bearings, utilize appropriate tools such as bearing extractors and torque wrenches to prevent unnecessary damage to the bearing or its housing.

Maintain the Bearing Environment:

When storing your motorcycle, ensure it is protected from harsh weather conditions.

Select suitable storage conditions to minimize corrosion and wear of the bearings.

Regular Inspections:

Establish a routine for periodic inspections of motorcycle bearings to detect potential issues early and take timely action to address them.

Maintaining motorcycle bearings may require patience and meticulous work, but it results in a longer-lasting motorcycle with improved performance and reduced repair costs. Keeping your motorcycle in top condition ensures a superior riding experience.

English

English 中文简体

中文简体

.png?imageView2/2/format/jp2)